Cab Progress

Quite a lot of progress has been made recently, partly because the hydraulic riveter is due to go back to Bo’ness soon. The cab sides have now been completely built, leaving only the roof to complete the structure.

|

| New Cab |

When the cab platework was produced by water jet cutting from the CAD drawings, all the fixing holes were included. However the angle irons and flat bar that is used to join it all together still needed to be cut and drilled to match, which was quite time-consuming. The angle irons all have one leg that is riveted to the panel and the other leg is bolted. This means that all the cab panels can be unbolted from each other.

|

| Another view of the cab |

|

| Rear view of cab |

The original joining bars and stiffeners were welded where they meet at the corners, which caused some distortion and prevented the rear and side panels from being separated easily. For the new cab, the corners are stiffened by short pieces of angle that are bolted to the bars. These bits are required to prevent the sides of the cab bending outwards slightly as you grab the handrails to climb up.

|

| Detail of corner stiffeners. Note rivets and stainless steel bolts. |

The lights and horn were temporarily fixed to the cab for the photographs.

The original cab roof was only in fair condition and had been bent when Queen Anne was hoisted out of its isolated bit of track back in 2010. It would have been possible to straighten it but some creases would still have shown. So it was decided to have a new roof sheet rolled and this should arrive soon. The original was made of two pieces welded together to produce a 6’2” by 7’6” sheet unrolled, but sufficiently large single sheets are now available. The curved angles that fix the roof to the cab ends will need to be modified as the curve of the new cab panels is slightly different to the originals.

Injectors

As described in an earlier blog post, our injectors were fitted with the wrong nozzles (VPH instead of VRH) when Queen Anne was at Longmorn. While the engine runs OK, it would run better if it had the correct nozzles. However neither complete injectors nor replacement nozzles are available now in spite of exhaustive searching.

|

| The injectors from Ebay |

Fortunately, a set of four second-hand VRH injectors were spotted on Ebay. Although not used for some time, two had been serviced and should work while the other two should be serviceable. A winning bid was submitted and we now have the injectors. So we should eventually be able to fit four injectors with the correct nozzle and still have one spare.

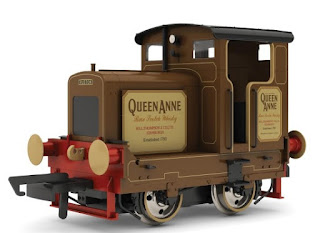

Queen Anne in Miniature

Hornby have just announced production of an 00-Gauge Ruston 48DS (click for details). It will be produced in four variants, one of which is Queen Anne as it was when it originally arrived at the Strathspey Railway. The model is a good representation of Queen Anne as it was around 1980. It must be based on photographs from the Internet as I am not aware of any approach by Hornby to the Strathspey Railway for details.

It is hoped that the model will prove popular and will help draw attention to our restoration project here at Aviemore.

The model is expected to be available in July 2019 and will most likely beat the restoration of the real Queen Anne. Finance is one of the limiting factors in the restoration, which relies on donations (eg. Strathspey Railway Association and Friends of Broomhill) and contributions from those carrying out the restoration (eg. the recent purchase of injectors on Ebay). The main items required for completion are brass-bound armoured cable (still available, but almost £200 to replace the life-expired originals) and fabrication of the engine bay louvre doors (which require specialist tooling to produce the rolled hem).