Gearbox and Transmission

Thanks to the generosity of the Friends of Broomhill Station, we have received a donation that has enabled us to buy a new drive chain. Fortunately 1.5 inch pitch heavy-duty roller chains are still available.

|

| The new drive chain |

The power from the engine is taken via a flexible coupling next to the flywheel to the Ruston patent constant-mesh gearbox, which has 3 speeds. This feeds the integral transfer gearbox, which moves the axis of rotation 90 degrees and is equipped with a forward-neutral-reverse lever. The output shaft, running across the gearbox, has a sprocket at each end driving the two axles via roller chain. The axles are suspended from adjustable-length swinging arms, whose pivots are approximately (but not exactly) in line with the transfer gearbox output shaft, so that the chain tension does not vary too much as axles move up and down. The adjustable swinging arms allow wear in the chains to be taken up.

|

| The new chain in place, before adjusting the tension |

The Ruston patent gearbox was designed in 1931 and used in almost all narrow-gauge and the smaller standard-gauge shunters with chain drive. It proved to be a robust and reliable transmission. Each gear ratio has its own friction clutch, and a system of interlocking selector levers ensures only one clutch can be engaged at a time.

It was noticed that the gearbox input shaft on Queen Anne had some side play, so the top gearbox cover was removed (it weighs 3 hundredweight). The input shaft runs in the upper cover supported by a ball bearing and a caged roller bearing. The ball bearing was not the original, and at some time in the past the shaft had been rotating inside the bearing. The roller bearing also seemed a bit noisy, so both were replaced with new British-made bearings. The worn shaft was built up with weld and machined back to the correct size. An extra rubber shaft seal was also fitted to prevent dirt entering the ball bearing.

The gearbox was also given a good clean out. Because it uses friction clutches, a lot of grey sludge is formed as the friction linings wear. Also the flange that joins the two parts of the casing had been damaged in the past and a corner bolt-hole had broken. A crude bracket held the broken part in place. The broken pieces were welded back using an arc welder and pure Nickel rods.

It was noticed that the gearbox input shaft on Queen Anne had some side play, so the top gearbox cover was removed (it weighs 3 hundredweight). The input shaft runs in the upper cover supported by a ball bearing and a caged roller bearing. The ball bearing was not the original, and at some time in the past the shaft had been rotating inside the bearing. The roller bearing also seemed a bit noisy, so both were replaced with new British-made bearings. The worn shaft was built up with weld and machined back to the correct size. An extra rubber shaft seal was also fitted to prevent dirt entering the ball bearing.

The gearbox was also given a good clean out. Because it uses friction clutches, a lot of grey sludge is formed as the friction linings wear. Also the flange that joins the two parts of the casing had been damaged in the past and a corner bolt-hole had broken. A crude bracket held the broken part in place. The broken pieces were welded back using an arc welder and pure Nickel rods.

|

| General view of the gearbox |

|

| The original worn roller |

|

| The new Cam Roller |

The Cab Floor

The cab floor consists of several steel panels which bolt together. The original design used nuts and bolts in some places, which meant access to both sides was required to remove sections of floor – essential to gain access to the gearbox etc. So it was decided to ensure all fixings were via countersunk screws that fitted into tapped holes in the supports. Stainless steel screws were used to prevent them from seizing up.

|

| Some of the floor panels and the fuel tank after painting |

While parts of the floor were supported on brackets on the chassis, the edges were originally supported by the cab sides, which in turn were attached to the chassis by a metal plate which was a rust trap. This arrangement was re-designed to use four pillars rising from the chassis at each side to support the floor close to the edge. Not only does this produce a more rigid floor, but the floor can now be a solid stand-alone platform without needing the cab to be present. Also the rust-trap at the bottom of the cab sides can be eliminated and be replaced by a simple stiffening bar.

|

| View showing the 4 vertical pillars towards the back |

The floor panels were bolted down with rubber pads underneath to reduce vibration. In future it should be a simple matter to remove a section of floor for maintenance purposes by undoing a few stainless steel screws.

|

| The outer floor panel is screwed to the 4 pillars |

Latest News

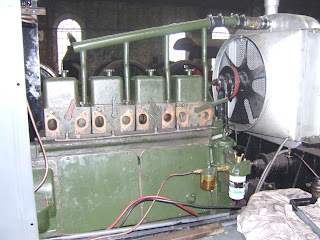

Here is a recent photograph showing the cylider heads in place and the reconditioned injectors fitted.

|

| A view of the engine |